DSEAR Compliant Cable Duct Sealing Systems

Your Responsibility

DSEAR is a UK H&S Law that places the responsibility on employers to assess, then eliminate or reduce the risks from dangerous substances within an asset (work area).

A Brief Overview

The Dangerous Substances and Explosive Atmospheres Regulations 2002 (DSEAR) came into force on 9th December 2002.

DSEAR applies to all dangerous substances at nearly every business, including HE, in the UK. It sets minimum requirements for the protection of workers from fire and explosion risks arising from dangerous substances and potentially explosive atmospheres.

DSEAR complements the general requirement to manage risks under the Management of Health and Safety at Work Regulations 1999 and addresses risk to persons safety from dangerous substances, as opposed to risks to health addressed by COSHH.

The impact of dangerous substances when exposed to fire can create a hostile and unpredictable environment. Dangerous substances can also create hazard through inhalation, particular attention should be given to the safe use and storage guidance supplied with the substance’s Safety Data Sheet (SDS). People should only work with potentially dangerous substances in an appropriately controlled and supervised environment with Control of Substances Hazardous to Health (COSHH) and Dangerous Substances and Explosive Atmospheres Regulations (DSEAR) assessments completed where required.

DSEAR requires that you:

- Carry out a risk assessment of any work activities involving dangerous substances with fire and explosion risks;

- Provide technical and organisational measures to eliminate or reduce as far as is reasonably practicable the identified risks;

- Provide equipment and procedures to deal with accidents and emergencies.

- Provide information and training to employees.

- Classify places where explosive atmospheres may occur into zones and mark the zones where necessary.

Arrangements must make explicit good practices for reducing the risk to persons from fires, explosions and similar energetic (energy-releasing) events that are in turn, caused by dangerous substances such as flammable solvents.

Guidance on what constitutes a 'dangerous substance' and how to complete the risk assessment is available below on the HSE website.

**Remember, even stagnant water if left over a period of time can give of methane!**

Products from AC Cable Solutions

In relation to cable duct sealing/cable entry sealing, It is crucial to use a product that can guarantee cable separation when being installed and support cables from coming in contact with entry walls therefore alleviating the risk of leak paths through the seal, A product must also have a pressure test certification to show it can prevent hazardous substances penetrating the seal itself. Products that don’t guarantee cable separation such as expanding foam are now outlawed in DSEAR compliant applications)

Duct Seal LG & Duct Seal HG are perfect products that provide the tools needed to separate cables to comply with DSEAR requirements:

Cable Separation

This is a critical area where many duct sealing systems are prone to failure.

Either the product doesn't support cable separation, or the installer has failed to separate the cables sufficiently.

Separating the cables can be a challenging task, and the main factor for making this easier is space and using an appropriate sealing system that has the components required for separating.

1. Plan the sensible use of multiple ducts where appropriate. Don’t try to cram each and every service into one duct. This kind of overpopulation makes any seal almost impossible to achieve.

2. If applicable, slightly over-size the ducts to ensure overpopulation does not occur. (A rule of thumb is usually maximum 50% cable fill per duct giving the opportunity for the ducts to be correctly sealed)

3. Include engineered duct sealing solutions as part of the project, and not as an after thought or a check box exercise.

4. Ensure your operatives are fully trained on duct Sealing – Its not as easy as some people think.

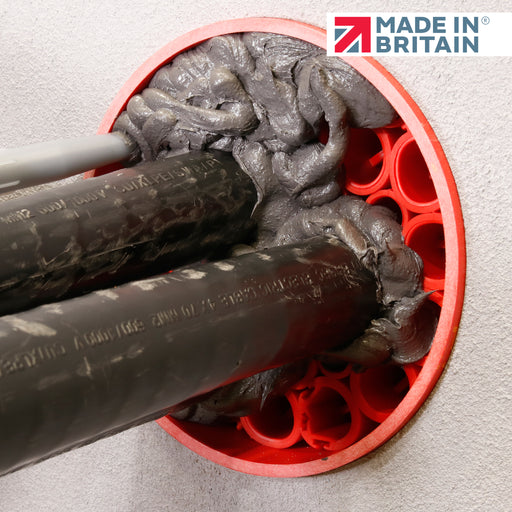

Examples of correct cable separation:

Benefits of Cable Separation

- Leak paths: By separating the cables while sealing the duct, you can effectively eliminate any potential leak paths for gas or water to penetrate

- Heat dissipation: Cable separation allows for better heat dissipation within the duct. When cables are tightly packed together, heat generated by one cable can transfer to adjacent cables, leading to overheating. By separating cables, you promote better airflow and reduce the risk of overheating.

- Reduced electromagnetic interference (EMI): Separating cables minimises the potential for electromagnetic interference between different types of cables. Electrical signals running through one cable can induce unwanted signals in adjacent cables, causing signal degradation or noise. By separating the cables, you can reduce EMI and maintain signal integrity

- Compliance with safety regulations: In some industries or applications, cable separation may be a regulatory requirement to ensure safety. Following cable separation guidelines helps adhere to industry standards and regulations, which are designed to minimise the risk of electrical hazards and ensure the proper functioning of the cables. Prime example; DSEAR Regulations.

The products listed below show why you should be using duct sealing systems from AC Cable Solutions.

Duct Seal LG

Duct Seal LG is a reliable solution designed to withstand up to 1 Bar of water, gas, and air pressure. It is primarily used when dealing with cables, each with a diameter smaller than 25mm

- Hydrocarbon resistant (petrol, diesel, ethanol, LPG, & Adblue)

- Resists toxic & corrosive gases (methane, hydrogen sulphite, & Chlorine

- 1 Bar water & gas-tight (10 meters of water)

- Non-Hazardous – Contains no MEKO

- Super easy to install

- Ensures cable separation (DSEAR Compliant)

- Wimes Section 3.02 2019 clause 6.4.3.2d)2 2019

Duct Seal HG

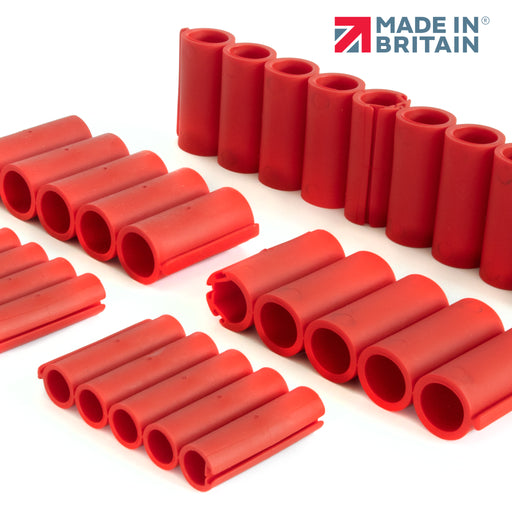

Duct Seal HG provides enhanced durability, offering up to 2 Bar resistance to water, gas, and air pressure. It is specifically designed to separate & support larger cables. The circular backing tubes can be interconnected to form a cross-piece for trefoil/triplex cables or a collar for quickly supporting single cables or pipes. The circular tubes can also be joined in groups of 5, split, compressed, or used as a whole unit to achieve a strong support around singular or multiple cables.

- Hydrocarbon resistant (petrol, diesel, ethanol, LPG, & Adblue)

- Resists toxic & corrosive gases (methane, hydrogen sulphite, & Chlorine

- 2 Bar water & gas-tight (20 meters of water)

- Non-Hazardous – Contains no MEKO

- Super easy to install

- Ensures cable separation (DSEAR Compliant)

- Wimes Section 02 2019 clause 6.4.3.2b)2 2019

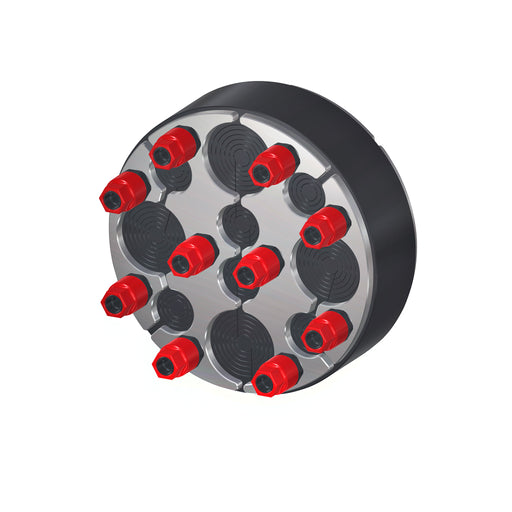

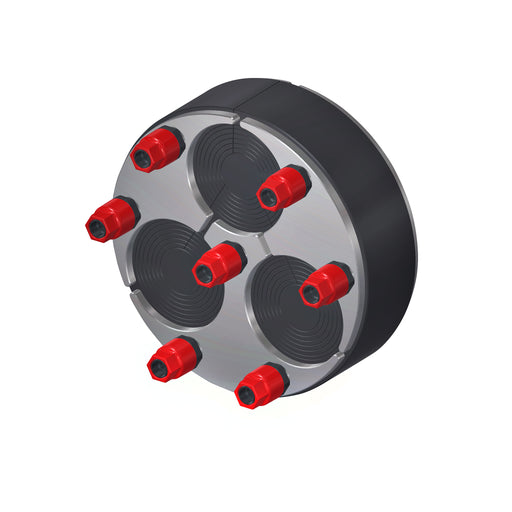

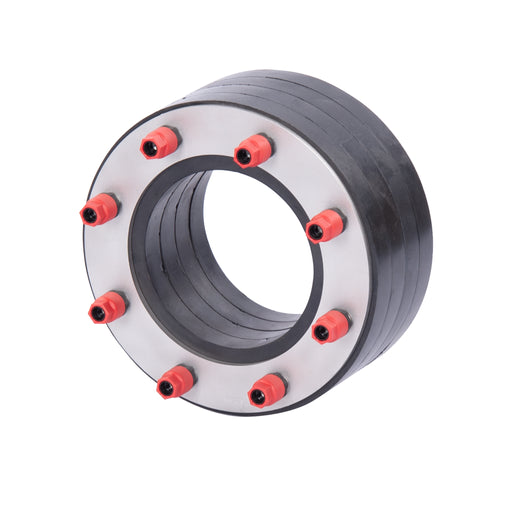

Kraso Universal Mechanical Seal

These seals offer various options catering to the most common duct sizes and cable configurations. Each cable port has peelable layers that can be cut away to the desired size to fit the outer diameter (O/D) of the cables.

- Hydrocarbon resistant (petrol, diesel, ethanol, LPG, & Adblue)

- Resists toxic & corrosive gases (methane, hydrogen sulphite, Chlorine & Radon gas

- Can be used with Running water

- Up to 10 bar Bar water & gas-tight (100 meters of water)

- Non-Hazardous – Contains no MEKO

- Super easy to install

- Ensures cable separation (DSEAR Compliant)

AC Cable Solutions is deeply committed to the importance of Duct Sealing and its associated regulations. Our comprehensive range of services includes expert advice, professional training, top-quality products, thorough surveys, precise drawing take-offs, and much more. When it comes to sealing cables, we boast extensive expertise, profound knowledge, and a wide array of specialised products to cater to your specific needs.

If you are unsure of what duct sealing system you should use, please contact AC Cable Solutions on 0161 806 1666 for help & advice.

The Law

Full DSEAR Regulations and Laws can be viewed on the link below. DSEAR Regulations - Fire and explosion (hse.gov.uk)

Written by Carl Pike - The Duct Sealing Man

DuctSeal Sealing Systems

-

Duct Seal FR Cable Duct Sealing System (fire resistant) - ≤2 Bar Pressure Resistance

DuctSeal POADescription Duct Seal FR is an innovative, low-smoke, zero-halogen duct sealing system designed for exceptional flexibility. It effectively seals a...

View full details -

Duct Seal HG Cable Duct Sealing System (large heavy cables) - ≤2 Bar Pressure Resistance

DuctSeal POADescription Duct Seal HG (Water & Gas) Duct Sealing System for Large Cables and Pipes Introducing the New Duct Seal HG (Water & Gas) System...

View full details -

Duct Seal LG Cable Duct Sealing System (cables <25mm Ø) - ≤1 Bar Pressure Resistance

DuctSeal POADescription Introducing the New Duct Seal LG (Water & Gas) Re-enterable Duct Sealing System The Duct Seal LG Cable Duct Sealing System is a rev...

View full details -

GreyStuff Intumescent Water & Gas Tight Duct Sealant

DuctSeal POADescription Grey Stuff is an exceptional single-component sealant, meticulously formulated with FyBrid technology, boasting neutral curing properti...

View full details -

RedStuff Intumescent Water & Gas Tight Duct Sealant

DuctSeal POADescription RedStuff is an exceptional single-component sealant, meticulously formulated with FyBrid technology, boasting neutral curing properties...

View full details

Kraso Sealing Systems

-

Kraso – Split Mechanical Duct Sealing System – Type Universal

Kraso POADescription The Kraso Universal circular cable transit seal is an optimal solution for cable entry through foundations & cable ducts offering e...

View full details -

Kraso – Customisable Split Mechanical Duct Sealing System – Type SD

Kraso POADescription The Kraso SD transit sealing system can be fully customised to accommodate any circular duct size and cable configuration. Like all of ...

View full details -

Kraso – 1.0 Bar – Single Pipe or Cable Duct Sealing System – Type ED

Kraso POADescription The Kraso ED system is designed for sealing single cables or pipes within concrete boreholes & ducted networks. Like Kraso's other ...

View full details -

Kraso – 3.0 Bar – Single Pipe or Cable Duct Sealing System – Type DD

Kraso POADescription The Kraso DD solution is meticulously crafted to effectively seal individual cables or pipes within concrete boreholes and duct network...

View full details -

Kraso – 8.0 Bar - Single Pipe or Cable Duct Sealing System – Type VD

Kraso POADescription The Kraso VD duct sealing system excels in sealing individual cables or pipes within concrete boreholes and ducted networks. The VD sy...

View full details