Kraso – 1.0 Bar – Single Pipe or Cable Duct Sealing System – Type ED

Description

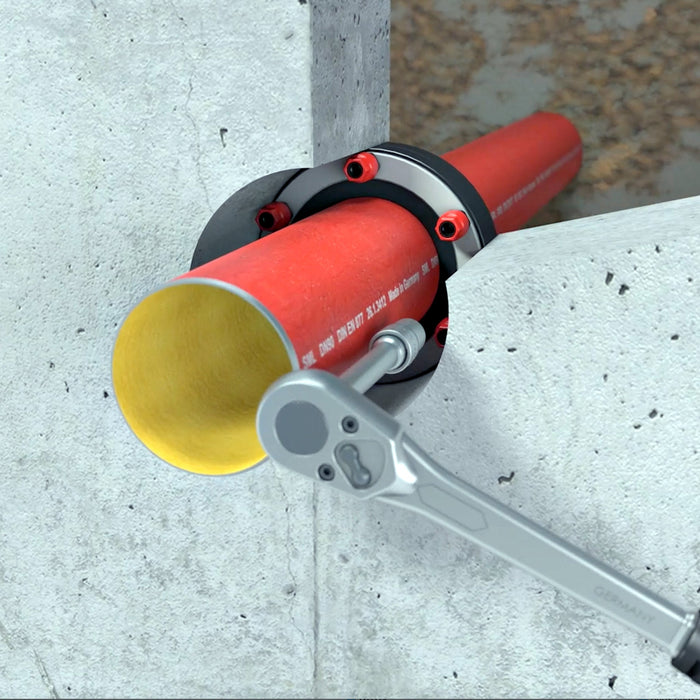

The Kraso ED system is designed for sealing single cables or pipes within concrete boreholes & ducted networks. Like Kraso's other duct sealing solutions, the ED circular transit seal provides durable defence against issues like flooding, gas penetration, moisture, and the entry of rodents. This seal consists of two elements, enabling straightforward installation, even in moist environments and regions with continuous water movement.

Tailored to excel in even the most demanding conditions, this duct sealing solution stands out distinctly. It prevails over formidable water and gas pressures, simultaneously warding off perilous and unsafe substances. Constructed from premium V2A stainless steel resistant to corrosion, this customisable ED penetration seal assures durability and reliability. Additionally, it integrates Kraso's patented Torque control nut, an exclusive feature that simplifies installation by ensuring the accurate tension of each nut. This innovative design eliminates worries about insufficient or excessive tightening, further enhancing its value.

Key Features

- Up to 1.0 Bar pressure resistance (10 meters of water)

- Patented torque nut - NO torque wrench required

- Resists Toxic Gases - Raydon, Hydrogen Sulfide, Methane & Chlorine gas

- Resists Hydrocarbons

Ordering

Type ED mechanical duct seal can accommodate duct sizes from up to 500mm, with most sizes available from stock. However, if the required size is not available from the lists below, we can make to order within 7 - 10 days.

Click to view on Kraso Website >>>

Summary

Kraso Type ED can be installed into sleeves, conduits and bored holes.

|

|

Specifications

|

Type of Test |

Result / Material |

Test Standard |

|---|---|---|

| Water Pressure Resistance |

1.0 bar / 20mm thickness of rubber |

MPA-Tested |

| Gas Pressure Resistance |

1.0 bar / 20mm thickness of rubber |

DIN EN 13611 (7.2) |

| RADON Gas |

Passed |

IAF Tested |

| Hydrocarbons |

Passed |

TBA |

| Gas Permeability |

Passed |

TA-Air |

| Temperature Resistance |

220◦C |

N/A |

| Metal Plates |

Non-corrosive Stainless Steel |

N/A |

| Sealing Rubber |

A specially developed mixture of rubber |

N/A |