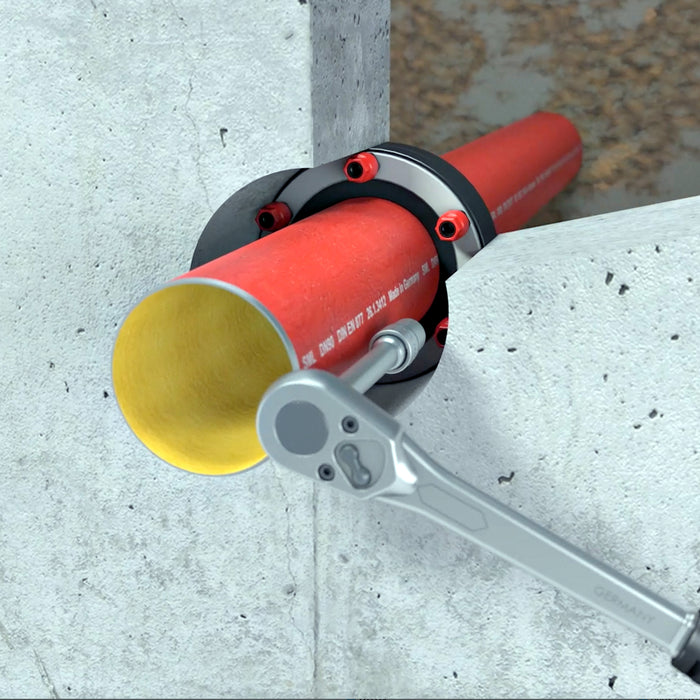

Kraso – 3.0 Bar – Single Pipe or Cable Duct Sealing System – Type DD

Description

The Kraso DD solution is meticulously crafted to effectively seal individual cables or pipes within concrete boreholes and duct networks. Similar to Kraso's range of duct sealing innovations, the circular transit seal of the DD system ensures robust protection against challenges such as flooding, gas intrusion, humidity, and the infiltration of pests. Comprising two components, this seal facilitates uncomplicated setup, even in damp surroundings and areas with constant water flow.

This duct sealing solution is designed to thrive under the most challenging circumstances. It conquers intense water and gas pressures while effectively repelling hazardous materials. Crafted from V2A stainless steel with exceptional corrosion resistance, the adaptable ED penetration seal guarantees robustness and dependability. Furthermore, it incorporates Kraso's patented Torque control nut, an exclusive attribute that streamlines installation by ensuring precise nut tension. This inventive concept eradicates concerns of inadequate or excessive tightening, adding to its overall significance.

Key Features

- Up to 3.0 Bar pressure resistance (30 meters of water)

- Patented torque nut - NO torque wrench required

- Resists Toxic Gases - Raydon, Hydrogen Sulfide, Methane & Chlorine gas

- Resists Hydrocarbons

Ordering

Type DD mechanical duct seal can accommodate duct sizes from up to 500mm, with most sizes available from stock. However, if the required size is not available from the lists below, we can make to order within 7 - 10 days.

Click to view on Kraso Website >>>

Summary

Kraso Type DD can be installed into sleeves, conduits and bored holes.

|

|

Specifications

|

Type of Test |

Result / Material |

Test Standard |

|---|---|---|

| Water Pressure Resistance |

3.0 bar / 40mm thickness of rubber |

MPA-Tested |

| Gas Pressure Resistance |

3.0 bar / 40mm thickness of rubber |

DIN EN 13611 (7.2) |

| RADON Gas |

Passed |

IAF Tested |

| Hydrocarbons |

Passed |

TBA |

| Gas Permeability |

Passed |

TA-Air |

| Temperature Resistance |

220◦C |

N/A |

| Metal Plates |

Non-corrosive Stainless Steel |

N/A |

| Sealing Rubber |

A specially developed mixture of rubber |

N/A |