The Best Duct Sealing Systems for Trefoil Cables

TREFOIL DUCT SEALING SYSTEMS

Trefoil Cables and How to seal them:

In the world of electrical installations, the demand for efficiency and reliability has led to the development of advanced cable systems, such as trefoil cables. These cables are designed to optimise power distribution, offering advantages in terms of performance and safety. However, the installation of these cables within ducts poses unique challenges, especially when it comes to sealing. In this blog post, we will delve into the intricacies of trefoil cables, the difficulties associated with sealing them within a duct, and how DuctSeal HG & Kraso’s mechanical seals emerge as the ideal solution for these challenges.

Understanding Trefoil/Triplex Cables:

Trefoil cables are specialised power cables commonly used in industrial settings and large-scale installations. The term "trefoil" refers to the unique arrangement of the three-phase conductors within the cable, forming a triangular shape. This configuration offers several benefits, including reduced electromagnetic interference, improved heat dissipation, and enhanced fault tolerance.

arrangement of the three-phase conductors within the cable, forming a triangular shape. This configuration offers several benefits, including reduced electromagnetic interference, improved heat dissipation, and enhanced fault tolerance.

Why do we use trefoil formation cables?

In the realm of low-voltage & medium power distribution, the utilisation of a trefoil arrangement in three-phase cables is a strategic choice rooted in electrical engineering principles. This configuration brings about a myriad of advantages, particularly in achieving a balanced and efficient system.

Balancing Inductive Reactance:

One of the key reasons for adopting the trefoil formation is its ability to balance the inductive reactance in each phase. The inductive reactance in a cable is proportional to its inductance, and by arranging the conductors in a triangular shape, trefoil cables ensure that the inductive reactance is nearly identical across all phases. This balance plays a pivotal role in equalising voltage drop during loading, resulting in a harmonious and stable system.

Equitable Current Distribution:

In wiring scenarios where multiple cable runs are connected in parallel, the trefoil arrangement becomes indispensable. When each parallel branch is configured in trefoil, the total current flowing through the cables divides almost equally between branches of the same phase. This equitable distribution ensures that each cable within the system is loaded uniformly. The significance of this approach becomes pronounced when delivering higher current capacity, preventing overloading of individual cables and enhancing the overall efficiency of the system.

Challenges of Sealing Trefoil Cables within Ducts:

While trefoil cables offer numerous advantages, their installation within ducts presents challenges that require careful consideration. The triangular arrangement of conductors can complicate the sealing process, making it difficult to achieve a secure and watertight duct seal.

Traditional sealing methods may struggle to accommodate the cable's shape and maintain the required integrity over time.

When it comes to sealing trefoil cables within ducts, the challenges go beyond the conventional concerns of sealing regular cables.

One of the most critical aspects is ensuring the complete separation of each of the single-phase conductors from each other and from the inside of the duct. The unique triangular arrangement of the three-phase conductors in trefoil cables adds a layer of complexity to the sealing process, making it crucial to address the separation issue for a reliable and durable duct sealing system.

the single-phase conductors from each other and from the inside of the duct. The unique triangular arrangement of the three-phase conductors in trefoil cables adds a layer of complexity to the sealing process, making it crucial to address the separation issue for a reliable and durable duct sealing system.

The trickiest part of this process lies in effectively splitting the three- phase conductors from each other and maintaining that separation throughout the installation. Most trefoil cables are cleated directly as they exit the ducts, meaning to make the installation easier, remove the cleats where and when possible.

phase conductors from each other and maintaining that separation throughout the installation. Most trefoil cables are cleated directly as they exit the ducts, meaning to make the installation easier, remove the cleats where and when possible.

What to avoid

Sealing systems, such as expanding polyurethane foam, and sealant-based systems utilising a soft, squidgy foam backing, may not guarantee the necessary level of separation. This can lead to potential failures in duct sealing systems, resulting in potentially flooded and unsafe critical buildings, such as substations..

COMPOUND SEALING SYSTEMS

What options do you have from AC Cable Solutions?

AC Cable Solutions has the answer for sealing trefoil cables, we have two duct sealing systems, a compound version, and a mechanical seal.

GAS & WATER TIGHTNESS

DUCT SEAL HG

Lets start with the compound version, Duct Seal HG

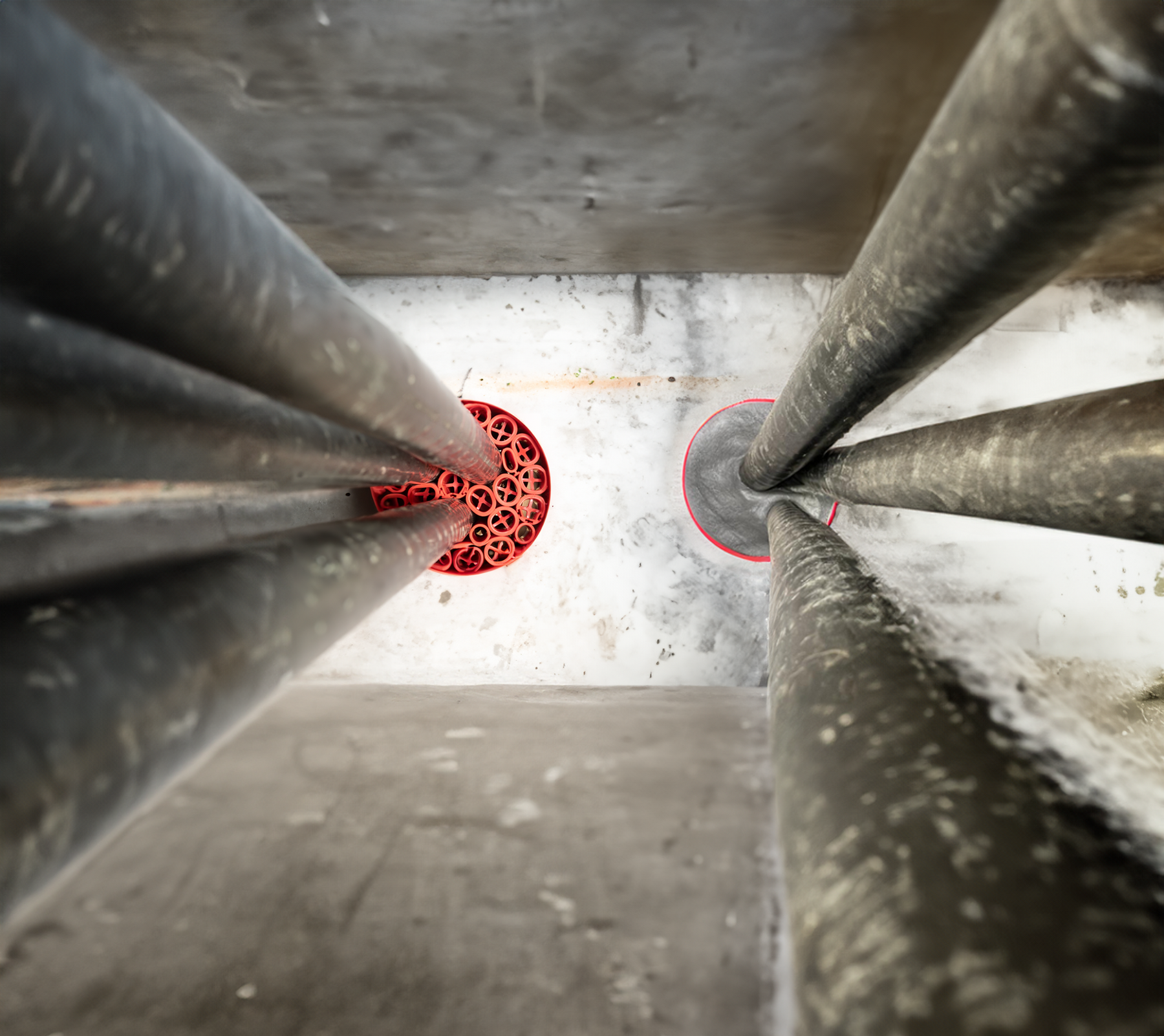

Duct Seal HG is the only duct sealing system, that allows you to build/create a cross shape to wedge in between the three single phases to create separation, to apply our GreyStuff sealant in & around the cables.

The tubes / sleeves are pushed in around the cables to fill up the space which creates support and seperation, then our GreyStuff Sealant is applied over the front to create a seal that has the following spealing specs & performance.

- Unique patented trefoil/triplex cable separation, setting the industry standard

- MEKO-free, Fybrid, and Non-Hazardous Intumescent sealant for enhanced safety

- Ensures water and gas tightness for superior performance - Up to 2.0 Bar

- Effectively resists toxic gases, making it an optimal choice for the Water Industry (methane, chlorine, & hydrogen sulfide)

- High resistance to hydrocarbons, making it ideal for the Petrol Forecourt industry - APEA & Blue Book

- Flame Retardant properties verified through UL94: 2013 ANSI / UL 94: 2018

- Compliance with DSEAR, WIMES, DCG, APEA, BLUE BOOK & ATEX standards

- Microbial Defense technology to boost resistance against fungi and bacteria

- Proudly MADE IN UK, with all components designed and manufactured locally

We have a patent pending on this design, which allows us to connect our circular sleeves, forming various shapes such as long strips or circular rings. As described above and depicted in the image below, this design creates a cross shape for trefoil separation

This is a unique and very effective way to ensure the separation, so by using Duct Seal HG, (which is the best compound seal for trefoil cables) you will easily seal and protect the duct, building & assets against water, gas & rodents.

Text to use for designing Duct Seal HG into specifications & drawings:

Water & Gastight Seal to 2 bar pressure comprises red tubular backing supports that can link together to form various shapes, for splitting trefoil cables and supporting larger heavier cables, and Fybrid Intumescent GreyStuff

Why Should you use Duct Seal HG- Duct Seal HG is always ex stock, available off the shelf ✔️

- As you can see from the information above, its perfect for Trefoil Cables ✔️

- No other compound sealing solution offers the cross peice for trefoil seperation ✔️

- Age tested for 50 years ✔️

- Made In Britian - Offical ✔️

- Supporting British manufacturing ✔️

- Full training (if required) with Fast technical support ✔️

- Re-enterable ✔️

- Non Hazardoues - Contains no MEKO ✔️ **Click to read this BLOG**

- No specialist tools required ✔️

- A friendly, helpfull, privately owned UK business ✔️

- Plus much more.....

IF YOU REQUIRE FIRE RESISTANCE

Introducing Duct Seal FR, a cutting-edge, low-smoke, and zero-halogen sealing system designed for optimal flexibility and safety. Engineered to accommodate various cable sizes, including large and heavy cables and pipes, this system ensures robust sealing within ducted networks. Duct Seal FR is specifically formulated to block the entry of harmful or flammable gases, liquids, fire, smoke, and pests. Notably, it has been rigorously tested and proven to provide up to 4 hours of fire resistance, meeting the stringent standards of BS EN 1366-3:2021

Key Features

- Fire Resistant up to 4 hours, tested to BS EN 1366-3:2021

- Intumescent technology, both for the sealant & sleeves

- One-of-a-kind patented trefoil/triplex cable separation - The best in the market

- Low Smoke, Zero Halogen

- MEKO-free, Fybrid, Non-Hazardous Intumescent sealant

- Fire, Water & Gas Tight

- Resists Toxic Gases - Ideal for the Water Industry (methane, chlorine, & hydrogen sulfide)

- Resists Hydrocarbons - Perfect for the Petrol Forecourt industry

- DSEAR, WIMES, DCG, APEA, BLUEBOOK & ATEX Compliant

- Microbial Defence - boosted to resist fungi & bacteria

- MADE IN UK - All components are designed and manufactured locally

Fire Resistance

- Up to 4 hours (240 mins) Fire Resistance (in both directions)

- BS EN 1366-3:2021 which supersedes BS EN 1366-3:2009

- Cables tested: Small, Medium, Large, Telecommunication & Bundles

- Cables types: NYY-O, N2XH-J, HO7V-K, J-Y(ST) Y

- Warrington Fire cable Ref: (B), (G), (D3), (F) & (E)

- Tested in horizontal penetrations up to 200mm (8 inches) in diameter

- Tested in 140mm thick low-density concrete walls (no duct or sleeve)

- Tested at Warrington Fire (Exova)

MECHANICAL SEALING SYSTEMS

The second option for sealing trefoil cables involves utilising a mechanical sealing system manufactured by Kraso GmbH and distributed by AC Cable Solutions.

With the mechanical seal, as it is the required practice for any type of duct sealing system, it is necessary to separate the three phases to facilitate the fitting of the mechanical sealing seal around the cables and into the duct.

How do the Kraso mechaincal seals work?

The Kraso sealing system features robust stainless-steel plates sandwiching a resilient EPDM rubber core. The magic happens with our patented self-torque-rated nut, which gently compresses the rubber. This compression causes the rubber to expand, forming a gas & watertight seal around your cables and the inner surface of the duct. The nut cannot be over-tightened; it clicks and spins around loosely when at the correct tightness.

a resilient EPDM rubber core. The magic happens with our patented self-torque-rated nut, which gently compresses the rubber. This compression causes the rubber to expand, forming a gas & watertight seal around your cables and the inner surface of the duct. The nut cannot be over-tightened; it clicks and spins around loosely when at the correct tightness.

Within the Kraso there are two options for sealing trefoil cables in ducts, which are the following:

Kraso Universal Seal

The Kraso Universal Seal is a versatile off-the-shelf solution that accommodates various duct sizes and cable configurations. It's designed to handle the most common duct sealing requirements encountered on-site. Each of the cable entries has peelable layers to accommodate the cable O/D.

The Kraso Universeal seal offers multiple options for various duct and cable diameters, all featuring flexible, easy-to-cut layers that can be adjusted to accommodate the size of the cable

diameters, all featuring flexible, easy-to-cut layers that can be adjusted to accommodate the size of the cable

Size chart below:

- 150mm duct, you would need (Version 1) for sealing trefoil cables,

- 200mm ducts, you would also need (Version 1), however you will then have 4 spare entries for future use.

The second option from Kraso involves utilising their mechanical seals, which can be customised to meet your specific requirements. In this case, no layers need to be cut away as the seal is tailored to your project needs, fully customised and ready for installation.

Kraso SD Customised

For those unique site conditions, Kraso's SD Sealing System can be tailored to match your specific cable and duct requirements.

Type SD mechanical duct seal can accommodate duct sizes from 50mm up to 500mm, with customised holes cut to the required number & size of cables that occupy the penetration.

Manufacturing lead times are generally 24 hours plus seven days shipping.

To enquire about this product to to recieve a quotion, please email the duct & cables szies to info@accablesolutions.com

A Kraso Seal will provide the following sealing performance as a minumum:

- Fully customisable - Please get in touch with us to receive more information.

- Can be installed with existing cables in place

- Up to 10.0 Bar pressure resistance (100 meters of water)

- Patented torque nut - NO torque wrench required

- Resists Toxic Gases - Raydon, Hydrogen Sulfide, Methane & Chlorine gas

- Resists Hydrocarbons

- Can be installed with running water

Conclusion: Trefoil Cable Duct Sealing with DuctSeal HG and Kraso Seals

In the realm of trefoil cable sealing, AC Cable Solutions stands as a beacon of innovation, offering two formidable solutions for safeguarding your infrastructure: DuctSeal HG and Kraso Seals.

Duct Seal HG - Unparalleled Versatility and Effectiveness:

DuctSeal HG, our compound sealing solution, takes cable protection to new heights. With its patent-pending design, it allows for the creation of a cross shape, ingeniously separating trefoil cables. The adaptability to form various shapes, coupled with the application of our GreyStuff sealant, ensures a robust barrier against water, gas, and rodents. Choosing DuctSeal HG is choosing unparalleled versatility and effectiveness in trefoil cable sealing.

Kraso Seals - Precision and Customisation Unleashed:

On the mechanical front, Kraso Seals redefine cable protection with precision and customisation. The stainless-steel plates and resilient EPDM rubber core, complemented by a patented self-torque-rated nut, create a secure, gas, and watertight seal. The Kraso Universal Seal offers off-the-shelf convenience, while the SD Customised Seal caters to unique site conditions, providing a fully tailored solution. With resistance to high pressures, toxic gases, and the ability to be installed with running water, Kraso Seals set a new standard for cable protection.

Choosing the Right Seal for Your Project:

Whether you opt for the innovative DuctSeal HG or the precision-engineered Kraso Seals, AC Cable Solutions ensures your project receives the tailored protection it deserves. DuctSeal HG excels in adaptability and compound sealing effectiveness, while Kraso Seals provide precision, customisation, and a diverse range of solutions to meet your unique requirements.

Get in Touch for Optimal Cable Protection.

The choice between DuctSeal HG and Kraso Seals boils down to the specific needs of your project. To explore these solutions further and receive personalised quotations, reach out to us at info@accablesolutions.com with your duct and cable sizes.

AC Cable Solutions – where innovation meets reliability for the safeguarding of your valuable infrastructure.

Written by Carl Pike - The Duct Sealing Man