Sealing Cable Ducts to Resist Chlorine Gas - CI

Introduction:

Water treatment plants play a critical role in ensuring the delivery of clean and safe drinking water to communities. In these facilities, various chemicals are used to purify water, and chlorine gas is a common choice for its effective disinfection properties. However, the use of chlorine gas poses potential risks, especially when it comes to cable ducts within these plants and other industries where methane is present. This blog explores the dangers of chlorine gas, the necessity of sealed cable ducts, and the importance of preventive measures to safeguard both human health and the integrity of industrial processes.

Chlorine Gas: Properties and Risks:

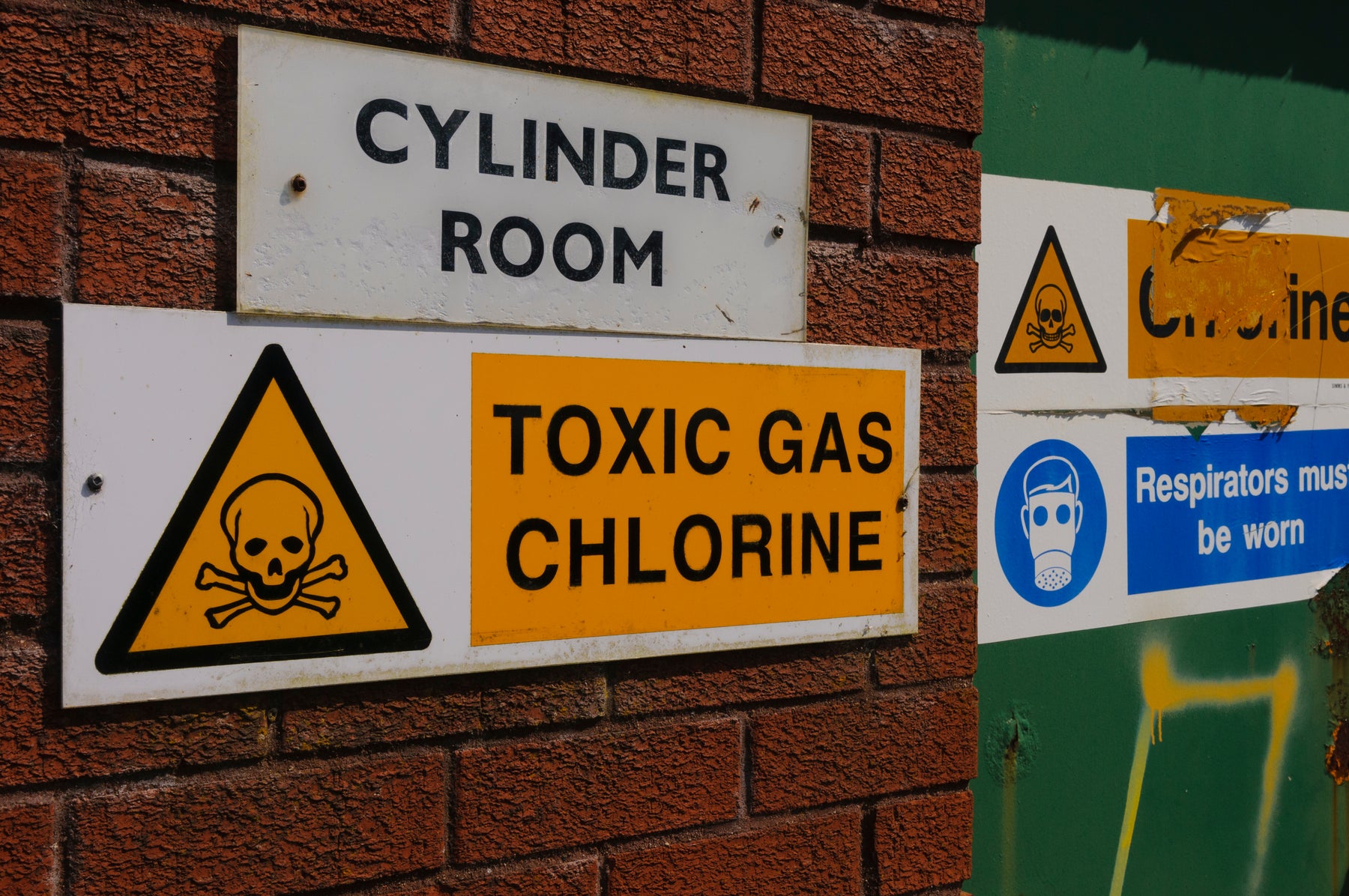

Chlorine gas is a highly reactive and toxic substance commonly used for disinfection purposes in water treatment plants. While effective in killing harmful bacteria and viruses, the gas can pose serious health hazards if not handled properly. Inhaling chlorine gas can cause respiratory distress, eye irritation, and, in severe cases, can lead to respiratory failure.

One of the challenges associated with chlorine gas is its ability to travel through cable ducts, which are essential components in water treatment plants and other industries. This migration can occur if the ducts are not adequately sealed, allowing the gas to escape and potentially harm workers and the surrounding environment.

Cable Ducts: Vulnerability to Chlorine Gas Migration:

Cable ducts are pathways used to route and protect electrical cables in various industrial settings, including water treatment plants. These ducts are often interconnected and can create an extensive network throughout the facility. If these ducts are not sealed properly, they become vulnerable to the migration of chlorine gas.

In water treatment plants, chlorine is commonly used in gaseous form, and its presence in the air poses a risk to cable ducts. If the gas infiltrates the ducts, it can compromise the integrity of electrical systems and equipment. Moreover, in industries where methane is present, the combination of methane and chlorine gas can create a potentially explosive mixture, heightening the risk of catastrophic incidents.

The Case for Sealed Cable Ducts:

Sealing cable ducts is a crucial preventive measure to mitigate the risks associated with chlorine gas migration. Proper sealing prevents the gas from infiltrating the ducts and spreading through the facility, protecting both personnel and critical infrastructure.

Several sealing methods and materials are available, each tailored to specific industrial needs. These may include DuctSeal LG, DuctSeal HG, or Kraso Mechanical seals and enclosures designed to create a robust barrier against chlorine gas intrusion. Regular inspections and maintenance are also essential to ensure the ongoing effectiveness of the seals

Beyond water treatment plants, industries working with methane or other hazardous substances should adopt similar precautions. Sealing cable ducts not only safeguards against chlorine gas but also contributes to overall workplace safety and the prevention of potential disasters.

Conclusion:

Chlorine gas is a powerful disinfectant used widely in water treatment plants and various industries. However, its potential risks, especially when migrating through cable ducts, underscore the importance of comprehensive safety measures. Sealing cable ducts is a fundamental step in preventing chlorine gas intrusion, protecting both workers and critical infrastructure. As industries continue to prioritise safety and environmental responsibility, implementing and maintaining proper sealing practices is essential for the sustained and secure operation of water treatment plants and other facilities.

To learn more about sealing cable ducts against Methane, please CLICK HERE

To learn more about sealing cable ducts against Hydrogen Sulfide, please CLICK HERE

Written by Carl Pike - The Duct Sealing Man