Duct Seal FR: The Best Solution for Fire Resistant Duct Sealing

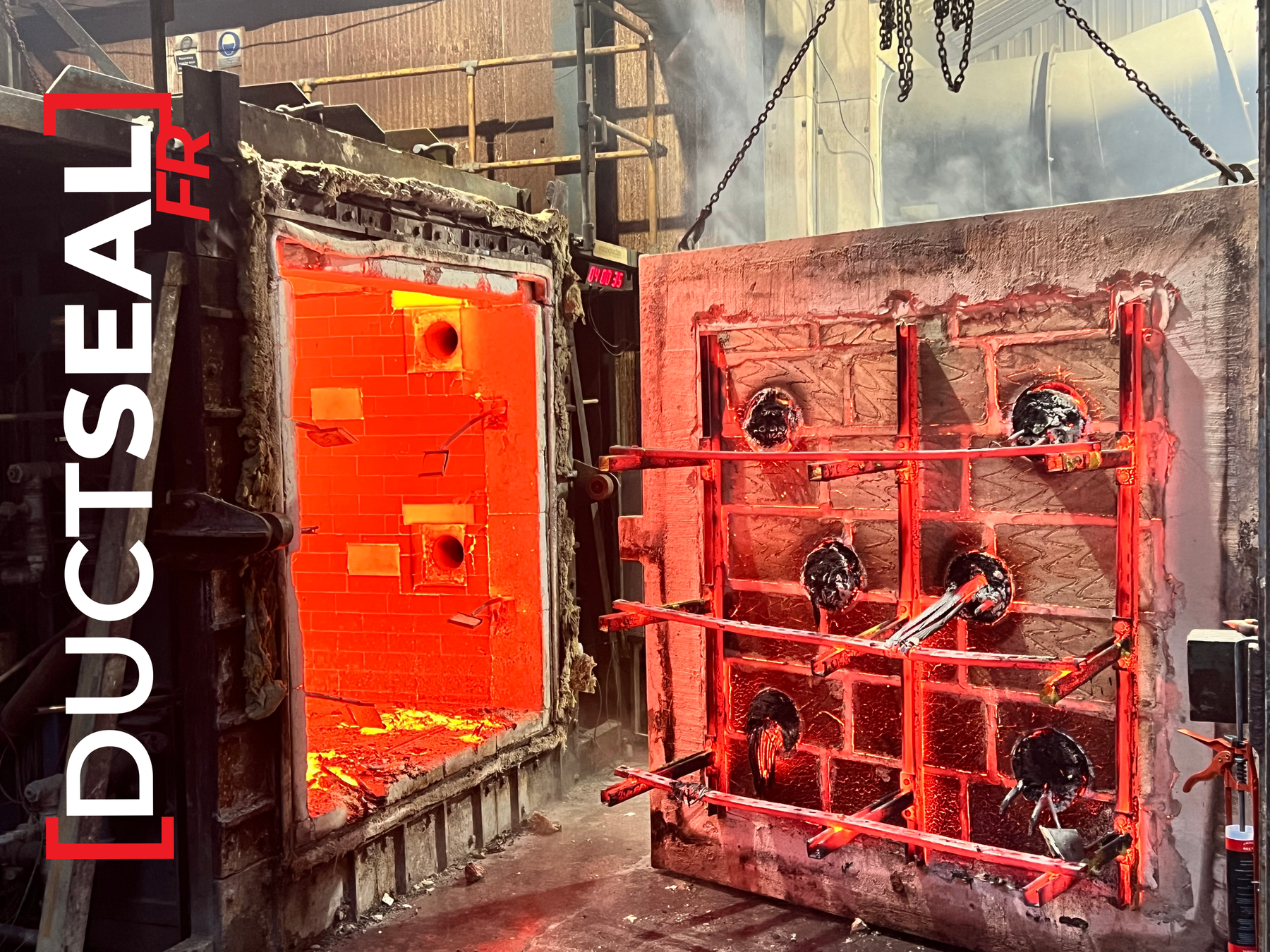

Picture shows, one of our directors, Carl Pike at Warrington Fire, after completing a 4 hour fire test of Duct Seal FR - tested to BS EN 1366-3:2021

Sealing Cable Ducts for Fire Resistance: Essential Knowledge for Safety

Sealing cable ducts for fire resistance is a crucial practice in building safety. This process involves using specialised materials to close openings where cables pass through walls or floors, preventing the spread of fire and smoke. This not only protects the structural integrity of a building but also ensures the safety of its occupants by maintaining the compartmentalization needed to slow down a fire’s progression.

The Importance of Proper Fire Stopping

Fire stopping is a fire protection measure that ensures that any gaps or

penetrations in fire-resistant barriers are sealed. In the context of cable ducts, this means using materials that can withstand high temperatures and block the passage of flames and toxic gases. Proper fire stopping can significantly enhance a building’s fire safety, giving occupants more time to evacuate and firefighters more time to control the fire.

The Dangers of Using Pink-Expanding Polyurethane Foam

A common mistake in fire stopping is the use of pink-expanding polyurethane foam. Despite its widespread availability, this type of foam should never be used for sealing cable ducts against fire. It is not designed to endure the high temperatures experienced during a fire and can fail, allowing fire and smoke to spread. This type of foam can degrade over time and under fire conditions, leading to catastrophic failures in fire protection systems. The foam's inability to intumesce or expand under extreme heat conditions means it cannot adequately seal gaps once cables burn away, leaving voids that compromise fire barriers.

There have been numerous instances where the use of pink-expanding foam has led to fire safety failures. For example, significant fire damage occurred in a building where pink foam was improperly used around cable ducts. The foam did not expand as needed during the fire, allowing flames and smoke to penetrate fire barriers, causing extensive damage and risk to occupants.

Fire rated foam or pink foam should only be used to fill small linear gaps, gaps between a door frame and wall - THATS IT, AT BEST, but even this should be questionable.

Fire Rated Expanding Foams - A Growing Concern

The use of so-called 'fire-rated' foams for fire stopping of service penetrations or control joints is sadly becoming more prevalent. This trend could lead to serious consequences if a fire occurs in a building where these foams are used.

What Are 'Fire Rated' Foams?

The 'fire-rated' foams in question are typically polyurethane-based and dispensed from aerosol cans or canisters, expanding upon release much like shaving foam. Despite being dyed red or pink to signify their supposed suitability for fire-stopping applications, these foams are not reliable for such critical uses. They often come from the same factories overseas and are imported under various brand names. However, their effectiveness in actual fire conditions is highly questionable, and their use is strongly discouraged.

Always call AC Cable Solutions, if you need to seal cables or pipes within a duct or bore hole. 0161 874 1470

The Journey to Developing DuctSeal FR

From the outset of founding AC Cable Solutions, we were committed to designing our own fire-resistant duct seal. However, we knew that rushing the process wouldn't yield the quality we demanded, so we decided to take our time to ensure we got it right.

The challenge lay in selecting the right combination of fire-resistant materials and ensuring a consistent and high-quality supply. There are only a few global suppliers of these specific materials, and some are controlled by exclusive customers, with one even being a competitor to the material supplier, you both know who you are.

Despite these hurdles, we decided to formulate our own intumescent granulate, which can be injection-molded or extruded. We have trademarked this innovation as FireStuff.

By utilising our circular sleeve system, designed to create separation and support cables made from FireStuff, in conjunction with our Fybrid GreyStuff or RedStuff intumescent sealant, we can achieve fire resistance of up to 4 hours in cable penetrations. This rigorous process of testing, re-testing, and refining our product to meet the BS EN 1366-3:2021 standard was not easy. It involved countless trials, quality checks, and overcoming numerous technical challenges. But the result, DuctSeal FR, stands as a testament to our commitment to quality and safety.

Recommended Solution: Duct Seal FR

DuctSeal FR fire sealing system is quickly becoming widely recognised and utilised by both UK and global utility companies to safeguard medium voltage (11kV/33kV) and high voltage (66kV/132kV) cables as they pass through substation ducts and enter buildings. This advanced sealing solution not only prevents water ingress that could lead to flood damage but also acts as a critical barrier against the spread of flammable gases within electricity substations, ensuring enhanced safety and operational integrity

For effective and reliable fire stopping, Duct Seal FR is an excellent choice. Here’s why:

- Fire Resistance: DuctSeal FR provides up to 4 hours of fire resistance, tested according to stringent standards like BS EN 1366-3:2021. This ensures it can withstand high temperatures and maintain its integrity during a fire.

- Intumescent Technology: The product features intumescent materials that expand when exposed to heat, sealing gaps effectively and preventing the spread of fire and smoke.

- Versatility: Suitable for various cable sizes and types, DuctSeal FR is easy to install and allows for maintenance without compromising fire resistance.

- Safety: It produces low smoke and zero halogen, reducing the risk of toxic fumes during a fire

-

Key Features

- Fire Resistant up to 4 hours, tested to BS EN 1366-3:2021

- Intumescent technology, both for the sealant & sleeves

- One-of-a-kind patented trefoil/triplex cable separation - The best in the market

- Low Smoke, Zero Halogen

- MEKO-free, Fybrid, Non-Hazardous Intumescent sealant

- Fire, Water & Gas Tight

- Resists Toxic Gases - Ideal for the Water Industry (methane, chlorine, & hydrogen sulfide)

- Resists Hydrocarbons - Perfect for the Petrol Forecourt industry

- DSEAR, WIMES, DCG, APEA, BLUEBOOK & ATEX Compliant

- Microbial Defence - boosted to resist fungi & bacteria

- MADE IN UK - All components are designed and manufactured locally

Fire Resistance

- Up to 4 hours (240 mins) Fire Resistance (in both directions)

- BS EN 1366-3:2021 which supersedes BS EN 1366-3:2009

- Cables tested: Small, Medium, Large, Telecommunication & Bundles

- Cables types: NYY-O, N2XH-J, HO7V-K, J-Y(ST) Y

- Warrington Fire cable Ref: (B), (G), (D3), (F) & (E)

- Tested in horizontal penetrations up to 200mm (8 inches) in diameter

- Tested in 140mm thick low-density concrete walls (no duct or sleeve)

- Tested at Warrington Fire (Exova)

Fire Certification

Important Note: A fire rating is applicable only to an "as fire tested" system or an

otherwise approved configuration. The entire system or configuration achieves the described fire rating only when a specific proprietary brand of product is installed in an identical manner to the approved tested configuration. Always ensure that your installation matches our fire test certification. It is the end user's responsibility to verify that DuctSeal FR is the correct system for the project requirements.

Benefits of Using Duct Seal FR Tested to BS EN 1366-3:2021

BS EN 1366-3:2021 is a rigorous standard that sets out the criteria for fire resistance testing of service installations, including duct sealing systems. Using a product like DuctSeal FR, which has been tested to this standard, ensures several benefits:

- Proven Performance: The testing criteria for BS EN 1366-3:2021 include exposure to high temperatures and direct flames to evaluate the product’s ability to maintain its sealing properties during a fire. Products passing this test are proven to provide effective fire stopping in real-world conditions.

- Comprehensive Safety: The standard assesses both the integrity and insulation properties of the sealing system. This means the product not only prevents the passage of flames but also limits heat transfer, reducing the risk of fire spreading through heat conduction.

- Reliability: DuctSeal FR’s compliance with this standard ensures it has undergone extensive testing for various configurations, providing reliable performance across different applications.

- Regulatory Compliance: Meeting BS EN 1366-3:2021 helps in achieving compliance with building codes and fire safety regulations, essential for legal and insurance purposes.

Testing Criteria for BS EN 1366-3:2021

The BS EN 1366-3:2021 standard involves several key testing criteria to ensure the effectiveness of fire-stopping products:

- Integrity: The ability of the seal to prevent the passage of flames and hot gases.

- Insulation: The ability to limit temperature rise on the non-fire side, preventing heat transfer that could ignite adjacent materials.

- Mechanical Stability: Ensuring the seal remains intact and functional despite physical stresses during a fire.

- Expansion Characteristics: For intumescent products, the ability to expand and fill gaps as materials burn away.

Note: This test standard supersedes BS EN 1366-3:2009. The main differences between the two standards include updated testing methodologies, enhanced criteria for mechanical stability, and stricter requirements for insulation properties. The 2021 version incorporates more rigorous testing to reflect current safety needs and technological advancements, ensuring a higher level of fire resistance and safety.

Fire Resistant vs. Flame Retardant: Understanding the Differences

When it comes to fire safety, terms like "fire resistant" and "flame retardant" are often used interchangeably, leading to confusion. However, these terms describe different properties and types of protection. Understanding the distinctions between fire resistant and flame retardant materials can help you make better-informed decisions for safety and compliance.

What is Fire Resistance?

Fire resistance refers to a material's ability to withstand fire and prevent it from spreading. Fire resistant materials are designed to endure high temperatures without melting or burning for a specific period. They are commonly used in building construction,Cable ducts & penertriations, fire doors, walls, and ceilings, to contain fires and provide critical evacuation time.

Key Characteristics of Fire Resistant Materials:

- Durability Under High Heat: Can endure prolonged exposure to fire without degrading.

- Non-combustible: Do not catch fire easily, making them ideal for structural applications.

- Code Compliance: Often required by building codes for safety and fire prevention.

Common examples of fire resistant materials include concrete, steel, and specific fire-rated glass, gypsum board, and fire rated mastics & silciones.

What is Flame Retardance?

Flame retardant materials, on the other hand, are designed to slow down or prevent the spread of fire and flames. Unlike fire resistant materials, flame retardant substances can still catch fire, but they do so more slowly, giving people more time to escape and reducing overall fire damage. These materials are treated with chemical compounds that inhibit ignition and combustion.

Key Characteristics of Flame Retardant Materials:

- Chemical Treatment: Often treated with flame retardant chemicals.

- Ignition Delay: Slows down the spread of flames.

- Versatility: Used in a variety of products, from textiles and electronics to building materials.

Examples of flame retardant materials include certain plastics, foams, textiles, and coatings that have been treated with flame retardant chemicals.

Key Differences Summarised

-

Performance in Fire:

- Fire Resistant: Withstands high temperatures and maintains integrity.

- Flame Retardant: Slows the spread of flames but may still burn.

-

Material Composition:

- Fire Resistant: Typically made of inherently non-combustible materials.

- Flame Retardant: Often made of combustible materials treated with flame retardant chemicals.

-

Applications:

- Fire Resistant: Used in structural components to prevent fire spread (e.g., fire doors, walls).

- Flame Retardant: Applied to a wide range of products to enhance fire safety (e.g., clothing, electronics, furnishings).

How Intumescent Products Work

Intumescent products, such as those containing expandable graphite, like Grey Stuff, red Stuff, and Duct Seal FR play a crucial role in fire stopping. These materials expand significantly when exposed to high temperatures, providing an effective seal against fire and smoke. Here’s how they work:

- Reaction to Heat: Upon exposure to temperatures above a certain threshold (typically around 200°C), intumescent materials undergo a chemical reaction. This reaction causes the material to expand many times its original volume.

- Formation of an Insulating Barrier: The expansion creates a thick, carbonaceous char layer. This char acts as an insulating barrier, protecting the underlying materials and preventing the passage of flames and hot gases.

- Sealing Gaps and Voids: As intumescent materials expand, they fill any gaps or voids left by cables or other penetrations. This ensures that fire and smoke cannot spread through these openings, maintaining the integrity of fire-resistant barriers.

Picture shows, before and after heat has been applied to our FireStuff intumescent material.

Expandable graphite is a common component in intumescent products due to its excellent thermal stability and expansion properties. When heated, graphite flakes expand and interlock, forming a dense and stable char layer that effectively blocks fire and smoke.

Conclusion

Ensuring fire safety through proper sealing of cable ducts is paramount in building construction and maintenance. Using specialised fire-resistant materials is essential to prevent the spread of fire and smoke, protecting both the structural integrity of buildings and the lives of their occupants. The dangers of using inappropriate materials, such as pink-expanding polyurethane foam, cannot be overstated. These materials are not designed to withstand high temperatures and can fail catastrophically during a fire.

Duct Seal FR, developed by AC Cable Solutions, represents a reliable and effective solution for fire stopping. With up to 4 hours of fire resistance, intumescent technology, and compliance with stringent standards like BS EN 1366-3:2021, Duct Seal FR provides comprehensive protection against fire, smoke, and toxic gases. Its versatility and ease of installation make it an ideal choice for various applications, ensuring both safety and regulatory compliance.

In summary, selecting the right fire-resistant products, such as Duct Seal FR, is crucial for maintaining high fire safety standards. Proper fire stopping not only enhances the safety of a building but also provides critical evacuation time for occupants and additional time for firefighters to control the blaze. Always verify that the fire-resistant products used in your project meet the required standards and are suitable for your specific needs to ensure maximum safety and protection.

Written by Carl Pike - The Duct Sealing Man