Duct Seal HG Cable Duct Sealing System (large heavy cables) - ≤2 Bar Pressure Resistance

Description

Duct Seal HG (Water & Gas) Duct Sealing System for Large Cables and Pipes

Introducing the New Duct Seal HG (Water & Gas) System

The Duct Seal HG system is a cutting-edge, re-enterable duct sealing solution designed for sealing large, heavy cables and pipes within ducted networks. This innovative system is engineered to prevent the ingress of harmful or flammable gases, liquids, smoke, and vermin, ensuring your installations remain safe and secure. Whether you're working on data centres, substations, or waste-to-energy plants, Duct Seal HG offers unparalleled protection and compliance.

Key Features of the Duct Seal HG System

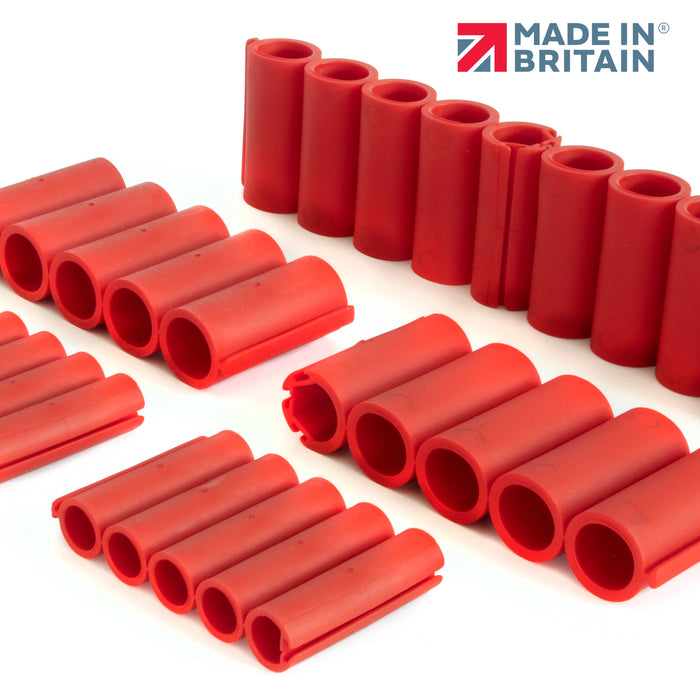

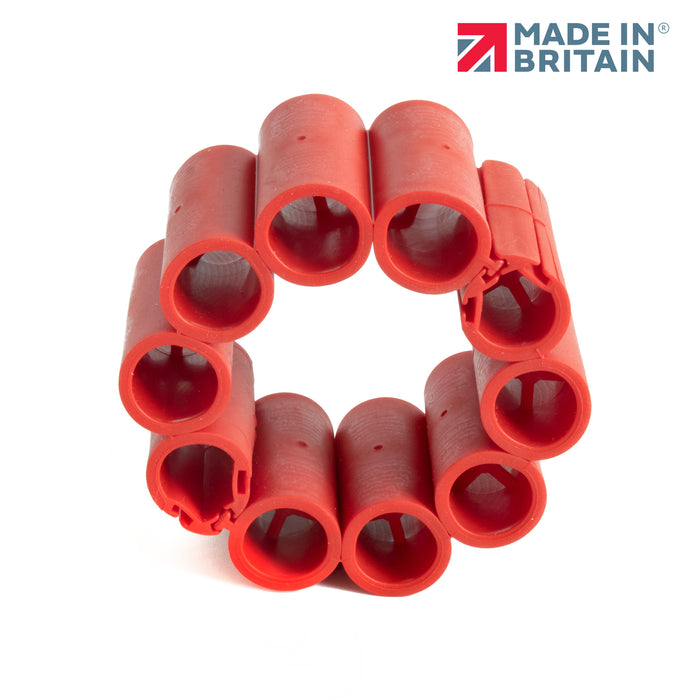

- Patent Pending Trefoil/Triplex Cable Separation: Our unique tubular rubber backing system can be configured in various ways—continuous strips, rings, or cross shapes—to provide optimal support and separation for large cables or pipes. This patented design ensures compliance with DSEAR and simplifies installation.

- MEKO-Free, Fybrid, Non-Hazardous Intumescent Sealant: Duct Seal HG uses our advanced Grey Stuff and Red Stuff sealants, which are flexible, zero-halogen, and free from MEKO, making them safe for installers and the environment.

- Water & Gas Tight: The system provides an impenetrable barrier against water and Gas, making it ideal for critical infrastructure applications.

- Resistant to Toxic Gases: Designed for the water industry, Duct Seal HG effectively resists gases like methane, chlorine, and hydrogen sulfide.

- Resists Hydrocarbons: Perfect for the petrol forecourt industry, the system is built to withstand exposure to hydrocarbons.

- Flame Retardant: Tested to UL94: 2013 ANSI / UL 94: 2018 standards, ensuring high levels of fire resistance.

- DSEAR, WIMES, DCG, APEA, BLUE BOOK & ATEX Compliant: Fully compliant with essential industry standards, making it a reliable choice for various sectors.

- Microbial Defence: Enhanced to resist fungi and bacteria, ensuring long-lasting protection in challenging environments.

- Non-Adiabatic: Minimal Cable De-Rating: At a thickness of 20mm, thermal resistance is just 5.1 K/W, preserving the cable’s full current-carrying capacity

- MADE IN UK: The Duct Seal HG system's components are proudly designed and manufactured in the UK, ensuring top-quality materials and craftsmanship.

Applications of the Duct Seal HG System

The Duct Seal HG system is versatile and suitable for a wide range of applications, including:

- Data Centres: Ensures secure sealing of large cables in critical data infrastructure, protecting against environmental threats.

- Sub Stations: Provides reliable duct sealing in electrical substations, preventing ingress of harmful substances.

- Pumping Stations: Ideal for water industry applications, where resistance to toxic gases and water-tight seals are essential.

- Waste-to-Energy Plants: Protects against harsh environmental conditions in waste-to-energy facilities, ensuring long-term duct integrity.

- Wind Farms / Turbines: Perfect for renewable energy installations, offering robust protection in exposed environments.

- Electrical Utilities: Ensures safe and secure duct sealing in various electrical utility applications.

- Rail Industry: Fully compliant with Network Rail standards, making it an ideal choice for rail infrastructure projects. (Network Rail Catalogue Numbers Available—Click Here)

Why Choose Duct Seal HG for Duct Sealing?

Duct Seal HG is not just another duct sealing system; it's a superior, patented solution designed to meet the highest industry standards. With its one-of-a-kind trefoil/triplex cable separation and advanced intumescent sealants, Duct Seal HG provides:

- Unmatched Flexibility and Protection: The re-enterable design allows easy maintenance and adjustments, while the unique backing system ensures optimal cable support and separation.

- Compliance and Safety: Fully compliant with DSEAR, WIMES, and other essential standards, Duct Seal HG is designed to keep your installations safe and compliant with regulations.

- Environmentally Safe and Non-Hazardous: Using FyBrid technology, the Grey Stuff and Red Stuff sealants are non-hazardous and environmentally friendly, ensuring safety for all users.

How to Install the Duct Seal HG Sealing System

Installing the Duct Seal HG system is straightforward and efficient. Follow these steps for a secure and reliable seal:

- Abrade the first 20mm of the duct and cables: This helps to remove any grease, old sealant, and dust, ensuring a clean surface for sealing.

- Clean the duct and cables: All debris, grease, and dirt must be removed to allow the sealant to adhere properly.

- Insert the larger tubes/sleeves: Start with the larger set of tubes or sleeves, inserting them into the duct and between the cables. Ensure proper separation between the cables and the inner duct. For trefoil cables, join the larger tubes to create a cross shape, maintaining separation between the three single cables.

- Fill smaller gaps: Use singular large or small tubes/sleeves to fill any remaining gaps, creating a tight and strong support structure.

- Adjust tube depth if necessary: If the tubes or sleeves are pushed too far back, use long-nose pliers to pull them forward, ensuring they are positioned 20mm deep from the duct edge.

- Apply the GreyStuff or RedStuff sealant: Start applying the sealant around the cables, working from the bottom up to ensure thorough coverage.

- Finish with the provided Magic Sponge: Wet and squeeze the provided Magic Sponge, then dab the GreyStuff or RedStuff sealant to ensure it has securely grabbed the cables and duct, leaving a neat finish.

- Completion: Your installation is complete, providing a secure and durable seal.

- Done

Frequently Asked Questions

What makes Duct Seal HG different from other duct sealing kits?

Duct Seal HG features a patented trefoil/triplex cable separation system combined with advanced FyBrid intumescent sealants. This unique combination offers superior flexibility, protection, and compliance with industry standards, making it the best duct-sealing solution on the market.

Is Duct Seal HG suitable for harsh environments?

Yes, Duct Seal HG is specifically designed to withstand harsh environmental conditions, making it ideal for applications in the water industry, petrol forecourts, and other demanding sectors.

Can Duct Seal HG be used for retrofitting existing installations?

Absolutely. The Duct Seal HG system's re-enterable design makes it perfect for new installations and retrofits, providing flexibility and long-term protection in any scenario.

Is Duct Seal HG WIMES Compliant?

It definitely is. DuctSeal HG is used by all UK water Authorities, including Ireland. The WIMES compliance number is 3.02 2019 clause 6.4.3.2D(b)

Related Products

Explore our full range of duct sealing kits, designed to meet the demands of various industries and cable sizes.

Why Buy from AC Cable Solutions?

AC Cable Solutions is dedicated to providing top-quality, British-manufactured duct sealing solutions. Our products are engineered to meet the highest performance and reliability standards, and our expert customer support team backs us.

| Product No. | Product | Duct Opening Max | Unit Sold |

|---|---|---|---|

| Using 1 x DuctSeal HG Kit – up to 100mm | |||

| DSHG100 | Duct Seal HG | 100mm | x1 Kit |

| Using 2 x DuctSeal HG Kits – up to 150mm | |||

| DSHG150 | Duct Seal HG | 150mm | x2 Kits |

| Using 3 x DuctSeal HG Kits – up to 200mm | |||

| DSHG200 | Duct Seal HG | 200mm | x3 Kits |

| Using 4 x DuctSeal HG Kits – up to 225mm | |||

| DSHG225 | Duct Seal HG | 225mm | x4 Kits |

| Using 5 x DuctSeal HG Kits – up to 250mm | |||

| DSHG250 | Duct Seal HG | 250mm | x5 Kits |

Installation

One Kit per Box

All components are included to seal 1 x duct as per the kit size mentioned (A caulking gun is not included but can be sold separately). ** One kit may fill more than one duct, depending on the cable % filled. Call 0161 806 1666 for advice**

Cable Separation

It's imperative to ensure separation between each cable and from the inside of the duct. Our unique daisy-chained circular tubes easily separate and support single or multiple cables.

Using our patent-pending tubular rubber tubes, various shapes can be made to help with cable separation, such as trefoil/triplex cables.

Running Water

For best results, the duct and cables should be dry with no running water. All dirt, oil, or grease must be cleaned before applying GreyStuff. If you have running water, please contact AC Cable Solutions for advice on 0161 806 1666. We recommend using a Kraso Mechanical seal —click here for further information.

Cure Time

Grey Stuff and Red Stuff will cure 3-4mm daily, depending on Humidity and temperature. The higher the humidity percentage and temperature, the quicker GreyStuff will cure. For an effective seal, a minimum of 20mm of Grey Stuff or Red Stuff is required.

Cleaning

Uncured material spillages can be cleaned with a solvent-based wipe.

Health & Safety

Grey Stuff and Red Stuff are based on a hazard-free neutral curing system to protect users when carrying out tasks like sealing cable ducts. Non-hazardous Zero MEKO.

Compliance

Duct Seal HG complies with WIMES, APEA, ATEX & DSEAR, SEWAGE FOR ADOPTION, and the DCG guidance.

Re-entry & Removal

Grey Stuff and Red Stuff will cure a similar hardness to a rubber eraser, so re-entry and removal are achievable. The ease of this depends on the type of tools used. For example, a sharper tool will be easier than a blunt-ended tool. Only use sharp tools when cables are de-energized. AC Cable Solutions accepts no responsibility for damaged cables.

Cable Suitability

Grey Stuff and Red Stuff is a single-component neutral curing system containing no solvents. Our formulation does not damage the properties of a cable sheath or stain surfaces.

Storage

Grey Stuff and Red Stuff should be kept in a cool, dry environment and away from sunlight. The product shelf life is 12 months. Once opened, any remaining product can be used for one month, provided the screwcap is securely fitted.

Features & Standards

| Water & Gas tight to 2.0 bar | Feature | Measurement | |

| Non-slumping | Density | 1.27 | |

| High bonding strength | Colour | Anthracite Grey or Brick Red | |

| Odourless when curing | Skin Over Time | 10 mins | |

| Flexible | Curing | 3-4mm per day | |

| Intumescent | Tack free time | 22 mins | |

| Very strong porous sticky char is formed when exposed to fire, which has excellent thermal insulation properties. | Hardness | 35 to 38 Shore A | |

| Microbial resistance – coverage against Fungi, E-Coli, Escherichia coli, Staphylococcus aureus, & A. brasiliensis | Elongation | 250% | |

| UV & Ozone resistant | Flow |

3.33 million cPs at 380°C | |

| Non-hazardous | Tensile strength |

0.72 N/mm^2 |

|

| Zero halogens used | Operating Temperature | +5 to 40°C | |

| Emits 0% MEKO | Temperature Resistance | -35 to +120°C | |

| Resistant to Hydrocarbons (Petrol, Diesel, ASTM oil, & LPG Gas) | Intumescence Activation Temperature | 210°C | |

| Resistant to Methane, Hydrogen Sulphide, & Chlorine gas – Independently tested. | Pressure Resistance | 2.0 Bar | |

| Resistant to many other gases & liquids, for example, ADBLUE & Antifreeze. | Shelf Life | 12 months | |

| Complies with DSEAR duct sealing regulations | |||

| WIMES compliant, as described in the WIMES Specification in section 3.02 2019 clause 6.4.3.2d) | |||

| Complies with 2011 NEC Articles 225.27, 230.8, 300.5(G), 300.7 (A) on Raceway Seals, and 501.15 (B)(2) | |||

| Petrol station forecourt accepted, as per the technology described in the APEA Blue book - 4th Edition, 4.6.8 | |||

| ATEX Compliant – Contains no moving parts or any form of material that can create a spark | |||

| Age tested to 50 years – Independently tested. | |||

Blogs

The following BLOGS provide additional technical information, tips and tricks, and do's and don'ts about our duct sealing system.

- To learn more about Trefoil cables > Click Here <

- To learn more about Network Rail PADS > Click Here <

- To learn more about Data Centres > Click Here <

- To learn more about WIMES compliance > Click Here <

- To learn more about APEA & Blue Book compliance > Click Here <

- To learn more about MEKO, and 2-Butanone oxime > Click Here <

- To help choose a duct sealing system > Click Here <

To view all our BLOGS revolved around duct sealing, > Click Here <