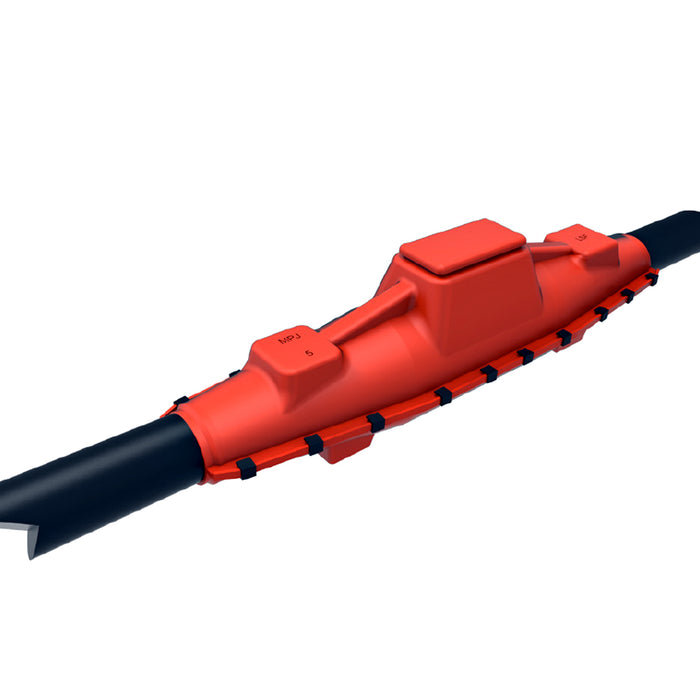

Prysmian BICON EFRZHMPJ Enhanced Fire Resistance & Zero Halogen Cable Joints

by Prysmian

Description

Prysmian BICON EFRZHMPJ Enhanced Fire Resistance & Zero Halogen Cable Joints and Kits are straight joints for Enhanced Low Voltage Fire Performance (FP) cables with copper conductors: Multi Core 4mm2 to 400mm2.

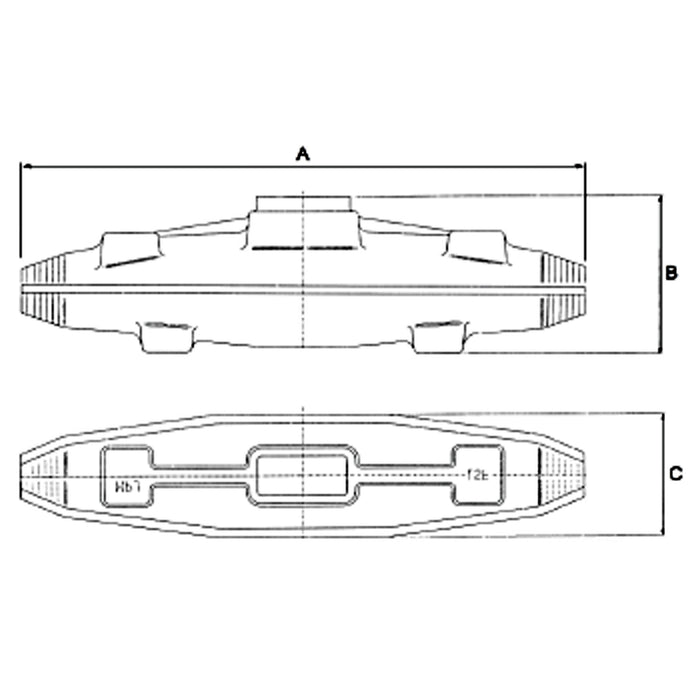

Shell Dimensions

| Product No. | A (mm) | B (mm) | C (mm) |

|---|---|---|---|

| EFRZHMPJ3 | 405 | 100 | 80 |

| EFRZHMPJ4 | 430 | 110 | 90 |

| EFRZHMPJ5 | 560 | 160 | 130 |

| EFRZHMPJ6 | 740 | 180 | 145 |

| EFRZHMPJ7 | 870 | 190 | 145 |

| EFRZHMPJ8 | 1015 | 205 | 180 |

Features & Benefits

- Rated voltage 1000V

-

Tested and approved to :

=> BS EN 50393:2015 – Test methods and requirements for accessories for use on distribution cables of rated voltage 0,6/1,0 (1,2) kV

=> BS EN 61034-2, IEC 61034-2 – Smoke Emission

=> BS EN 60754-1 , IEC 60754-1 – Acid Gas Emission

=> BS 6387:2013 – Test method for resistance to fire of cables required to maintain circuit integrity under fire conditions (categories C,W & Z)

=> BS 8491:2008 – Method for assessment of fire integrity of large diameter power cables for use as components for smoke and heat control systems and certain other active fire safety systems (120Mins) - Use with BS 7846 (F2,F30,F60, F120) Fire Resistant FP Cables

- System Requirements : BS 8519 Cat 3 & BS 5266-1 (120min)

- Low Hazard Isocyanate Free JEM resin

- Twin pack mixing in clear laminate sachets

- Extremely low viscosity resin with enhanced adhesion

- Rigid glass reinforced phenolic joint shells which are both fire retardant and LSOH.

- Slim-line design for use with compression connectors.

Technical Information

- LV Straight Joints for 600/1000 Volt fire Performance polymeric insulated SWA cables with copper conductors.

- Tested and approved to BS EN 50393 : 2015

-

Fire tests on completed joints to:

- BS 6387 categories C,W & Z

- BS 8491:2008 – 120Mins Combined Fire, Impact & Water Jet

-

Reaction to Fire tests to:

- BS EN 61034-2 , IEC 61034-2 – Smoke Emission

- BS EN 60754-1 , IEC 60754-1 – Acid Gas Emission

-

JEM Resin

=> Easier mixing in “Twin Pack” totally enclosed mixing in a clear laminate sachet.

=> Extremely low mix viscosity allows void Free joint filling

=> JEM Resin is insensitive to moisture and will cure under water.

=> High flash point, non-flammable liquid – No special storage or transport requirements.

=> Does not cause skin sensitisation.